Manufacturing Capabilities

MANUFACTURING NEXT-GENERATION MEDICAL DEVICES

TECHNOLOGY AND EXPERTISE TO ENSURE YOUR SUCCESS

We apply our extensive manufacturing capabilities to deliver precision solutions with excellence. We combine tailored development services with high quality, cost-effective manufacturing processes to ensure your project success.

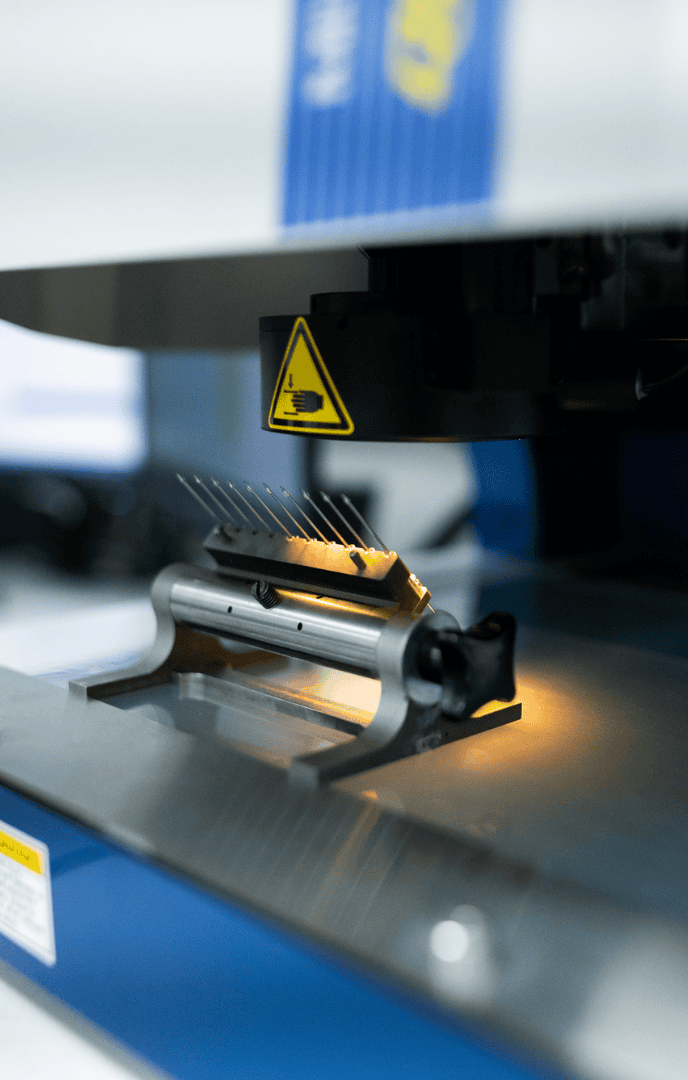

LASER TECHNOLOGY

Our temperature-controlled Laser Technology Center employs

high-volume production equipment and purpose-built systems to meet your component requirements. We laser cut features in tube from 0.2 mm to 20 mm, and our minimum kerf width of 0.012 mm enables us to meet your component design needs.

4-axis tube laser cutting, providing off-axis profiles on four separate systems

High-precision, flat-bed micro-laser cutting

Micro-laser welding, including automated welding systems (0.1mm spot size)

Laser marking on metal or plastic with distinct matte black finish

Laser cutting on stainless steel and Nitinol

Laser ablation providing engraved surface text, features or mold keys

MICRO-MACHINING

Elevaris Medical operates full 4D design and machine programming systems. We can interpret customer requirements via drawings or computer models, and quickly establish feasibility and delivery plans.

We utilize proprietary combination of laser technology, EDM wire erosion and sink erosion, 5-axis CNC machining and 3D Metal Printing Technology to ensure we can uniquely meet our customers’ high expectations in component manufacturing.

GRINDING

Our engineers use grinding technologies from standard bevel grinds to specialized designs like those needed for trocar or micro needles. Count on us for these grinding methods and tip styles:

Centerless grinding for precision solutions

Computer Numerical Control grinding for precise, repeatable grinding of complex needle tip geometries

Electrochemical grinding, which allows for highly precise and burr-free tip grinding

Standard Bevel and A&B Bevel grinds

Lancet points, suitable for precise cutting and sampling

Trocar grinds, designed for creating access points in minimally invasive procedures

Diamond points, durable, multi-faceted tips

Micro needles, often used for diagnostics and drug delivery

INJECTION MOLDING

Injection molding is a manufacturing process where molten material is injected into a mold cavity, where it cools and solidifies, creating a part with the desired shape. This process is commonly used for plastics, but can also be used for other materials like metals and glasses. The process involves several key steps: clamping the mold, injecting the molten material, holding pressure, cooling, opening the mold, and ejecting the part.

INSERT MOLDING

Insert molding is a specialized injection molding technique that integrates pre-formed components, often metal inserts, into a plastic part during the molding process. Molten plastic is injected into a mold containing the insert, bonding it to the plastic and creating a single, integrated component. This process enhances durability, functionality, and can reduce assembly steps.

CLEANROOM ASSEMBLY

We have world class cleanroom assembly areas in both our manufacturing locations.

Our ISO Class 7 and Class 8 cleanroom assembly areas have been developed for a number of specific customer products. This has provided a wide range of assembly capabilities, from packaged needles to hypo-tube catheter delivery systems.

We can support both development and production volumes.

Cleanroom assembly capabilities consist of:

Metal and polymer component cleanroom sub-assembly

UV and air-cured adhesive bonding

Automated heat shrinking with FEP & PET tube

PTFE tube inner liner installation

Automation - hi-speed assembly and inspection

Packaging and pouching

Testing and qualification

-

The Elevaris Product Assembly Group carefully designs and manufactures each component to meet stringent quality standards. We also offer quick turnaround times with our assembly and packaging services to make the process easier for you.

Our highly efficient and automated assembly capability, with fully validated packaging processes, is available for companies looking for contracted packaging solutions to market their products as quickly and easily as possible.

We also offer an array of packaging, private-label, and EtO sterilization options to meet your needs.

For low-volume operations, our team can hand pack your product into Tyvek® pouches that we then can label and sterilize.

Our state-of-the-art MULTIVAC packaging solution is a great option for high-volume components or finished goods. We can configure our MULTIVAC to incorporate Tyvek or paper, depending on your sterilization process objectives. Both options ensure that your product coding and marking is compliant with UDI requirements for traceability.

PRECISION FORMING

Precision forming is a cornerstone process in medical device manufacturing, enabling the mass production of complex, high-strength components with micron-level accuracy. We know that performance, reliability and compliance are non-negotiable, so we use precision forming in:

Swaging for reduction and pointing

Bending and shaping

Pressing and flattening

METAL FINISHING

Metal finishing enhances surface properties, functionality, and biocompatibility and plays a vital role in ensuring that metal parts meet strict medical standards for performance, cleanliness, and safety. We use metal finishing in the following processes:

Electropolishing

Chemical Etching

Passivation

Siliconization

Chrome plating